TOP ENTRY AGITATORS

TOP ENTRY AGITATORS

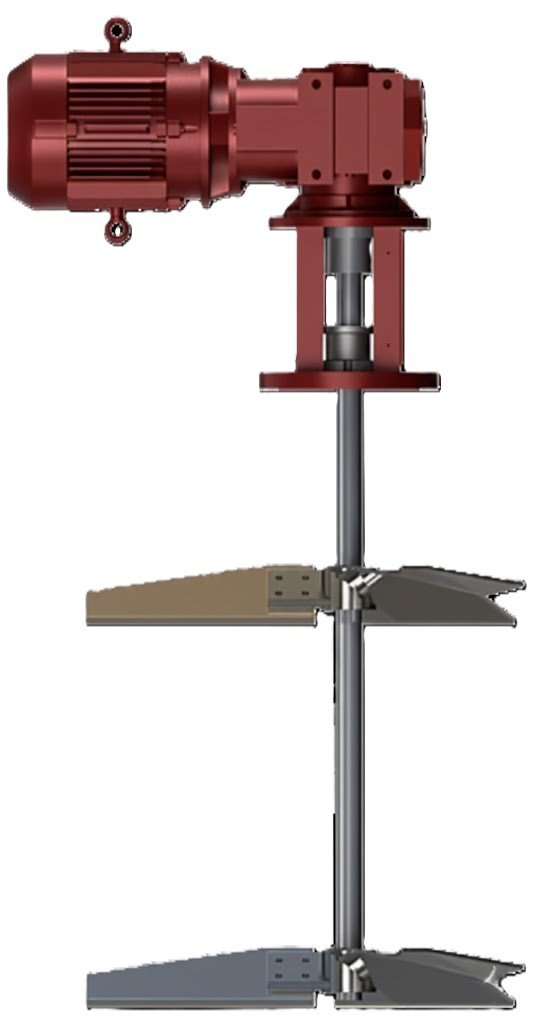

Top entry agitator: The top entry agitator is the most suitable and widely used device for mixing in every industry. Various impeller combinations are available and can be selected based on the application. Sealing systems such as single/double mechanical seals, stuffing boxes, vapor seals, and lip seals are used with reputed makes, selected according to design pressure and temperature. The seal can be removed using a spacer coupling, with or without dismantling the entire agitator.

Agitators are available with or without bottom support options. Motor power is determined based on the specific gravity, viscosity of the fluid, and the mixing application. Gearbox selection is based on RPM, safety factor, and bearing housing construction.

Top Entry Agitators

Top entry agitators are the most widely used industrial mixing systems, engineered to deliver high-efficiency blending, dispersion, and homogenization across all major industries. They offer flexible impeller options, advanced sealing mechanisms, and durable construction suitable for light, medium, and heavy-duty applications.

High-Efficiency Top Entry Agitators

Designed for reliable and consistent mixing performance in tanks, vessels, and industrial reactors across all sectors.

- Most suitable and widely used agitator type in industry

- High mixing efficiency for liquid-liquid, solid-liquid systems

- Multiple impeller combinations as per application

- Suitable for blending, dispersion, emulsification & homogenization

- Available in SS304, SS316L, Duplex, and custom alloys

Advanced Sealing Systems

A variety of sealing systems are used to prevent leakage, protect the shaft, and ensure reliable operation under demanding pressures and temperatures.

- Single & double mechanical seals with reputed brands

- Stuffing box, vapor seal & lip seal options

- Seal selection based on pressure & temperature

- Easy seal removal with spacer coupling

- Seal replacement without removing full agitator (optional)

- Compatible with ATEX / flameproof requirements

Motor, Gearbox & Support Options

Every agitator is engineered with the correct motor, gearbox, and support configuration to ensure safe, efficient, and long-life operation.

- Motor power decided based on viscosity, density & mixing duty

- Gearbox selected based on RPM, safety factor & bearing life

- Heavy-duty gearbox housing for long operation

- Top entry agitators available with / without bottom support

- VFD speed control compatibility for process optimization

- Designed for batch, continuous & high-torque operations